On August 15, 2025, the new version of the "Compulsory Product Certification Implementation Rules" was officially implemented, marking an important adjustment to the CCC certification for pouch batteries. As a core component of consumer electronics such as mobile phones and laptops, the safety certification of pouch batteries has become a hard threshold for market access.

The most notable change in the new version of the rules is that the certification mode has been changed from "issue the certificate first and then audit the factory" to "audit the factory first and then issue the certificate", and a new initial factory inspection step has been added. This means that enterprises need to first pass the full-process production review, covering more than 20 key procedures from the selection of positive and negative electrode materials to the assembly of finished products, before they can enter the product testing stage. After obtaining the certificate, the enterprise will also face up to four surprise flight inspections each year, and key links need to be fully recorded in video for traceability.

The testing standards for pouch batteries are based on GB 31241-2022, covering two major dimensions: electrical safety and environmental safety. Through extreme working condition tests, environmental adaptability tests, and physical protection tests, it ensures that the batteries do not catch fire or explode in complex scenarios. At the same time, targeted testing plans are designed to match the aluminum-plastic film packaging characteristics of pouch batteries.

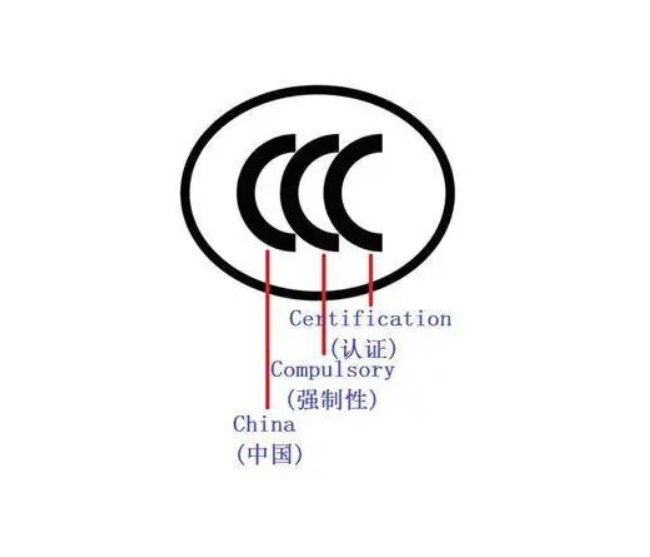

For enterprises, CCC certification serves as a "pass" to enter the market. Starting from August 2024, products that have not obtained the certification will be prohibited from sale. The certification process includes sample testing, factory inspection and annual supervision, etc. You can choose a qualified institution to handle it. Consumers can distinguish authenticity through "three looks" : look at the CCC mark on the product itself, check the certificate number on the official website of the Certification and Accreditation Administration, and verify the standard number on the packaging.

This mandatory certification is essentially to add a "safety insurance" to pouch batteries. From raw material control to production process supervision, and then to extreme condition testing, every step is strictly controlled to build a product safety defense line. For enterprises, certification serves as a reverse push mechanism for quality control. For consumers, the certification mark is an important proof of reassuring consumption.