The UL 4200A-2023 report is mandatory for button batteries because the U.S. Consumer Product Safety Commission (CPSC) has made it a mandatory consumer product safety rule to address the serious threat that button batteries pose to children's safety. The implementation of this standard aims to reduce injuries and deaths caused by children aged six and under swallowing button batteries by mistake. UL 4200A-2023 requires that product design should prevent children from easily opening the battery compartment, and stipulates detailed standards for product structure, testing, warning labels and instructions to ensure that products containing button batteries meet strict child protection and safety requirements. Through enforcement, ensure that all relevant products undergo safety verification before entering the market, thereby protecting consumer safety, especially that of children.

In the process of complying with UL 4200A-2023 standards, products containing button batteries need to pass a series of key tests to ensure their safety and reliability. The main test requirements include:

Drop test, impact test, compression test, torque test, tensile test, compressive strength test, etc.

1. Signing a contract: The client signs a consignment testing contract with the testing company, clearly defining the service items and ensuring the rights and interests of all parties.

2. Application for case opening: The client needs to submit the certification request form, relevant materials and test samples, and confirm the certification application information.

3. Sample testing: The laboratory tests each sample item by item in accordance with the standards.

4. Issuance of certification by the institution: After the review is passed, the certification body will issue the certification certificate.

According to the standard, for terminal products with "batteries that allow users to move or replace", the structural requirements are as follows:

The product design must ensure that the test probe No. 11 of IEC 61032 does not come into contact with the battery. During the inspection process, when the casing can be easily opened (at least two consecutive actions are required to open it by hand), an opening assessment must be conducted.

2. To prevent children from moving the battery, the product design requires a tool (such as a screwdriver or a coin) to open the battery cavity. When opening, at least 0.5Nm of torque and at least 90 degrees of rotation Angle must be applied, or the fastener must mesh at least two complete threads. In addition, if the cover is opened by hand, at least two independent consecutive actions are required to open the cover or door of the battery cavity.

3. If the cover or door of the battery cavity is fixed by screws or similar fasteners, the fasteners must be designed to be confined to the cover or door, for example, using screws that do not loosen.

4. When a product is equipped with a "battery that does not allow users to move or replace it", it is necessary to effectively prevent users or children from removing it. The product should be designed in such a way that the battery cannot be touched through the casing or similar means, or the battery should be completely fixed through welding, riveting or similar methods.

According to the standard, the requirements for product warning statements are as shown in the following figure

Note: If the product space is insufficient, the following sign can be used instead of a warning statement. This sign must be redefined and explained in the instruction manual and other materials.

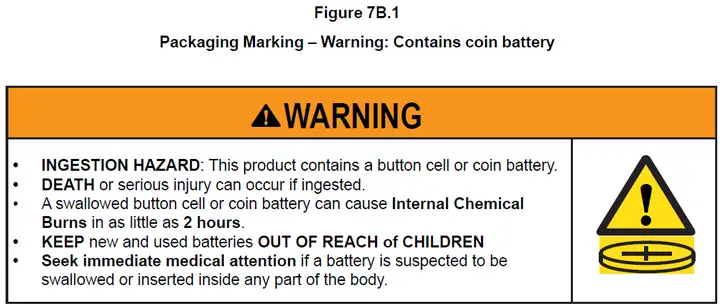

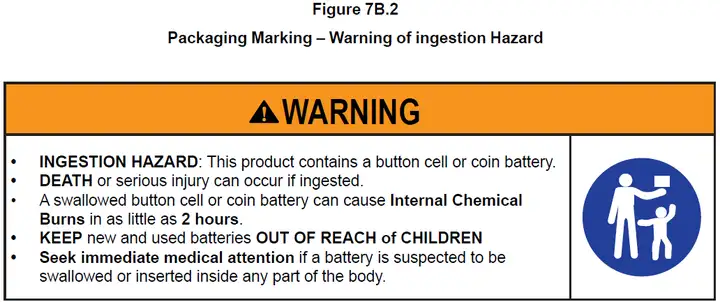

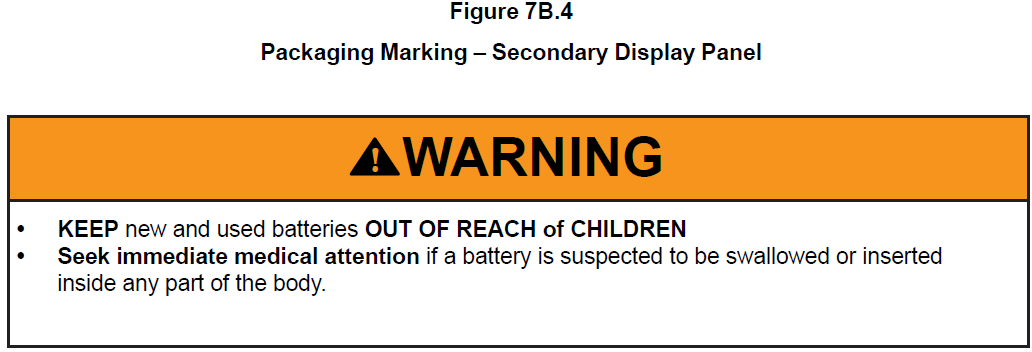

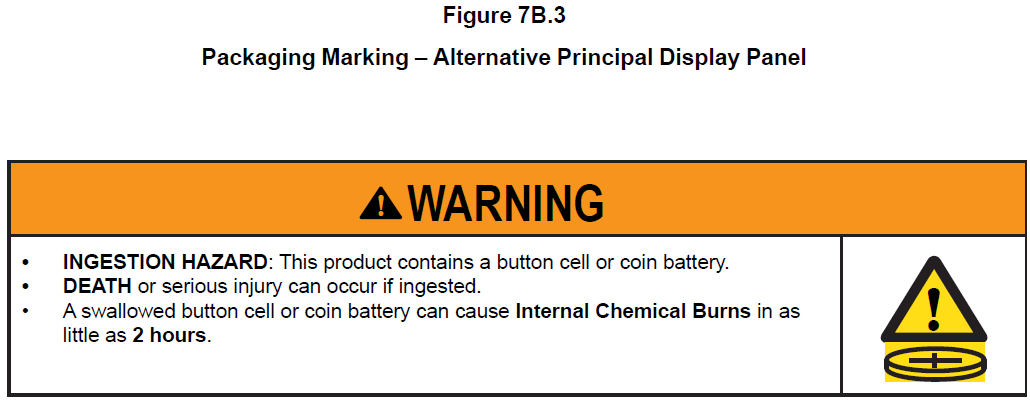

According to the standards, there are also certain requirements for warning statements on product packaging. The specific requirements are as follows.

If there is sufficient packaging space, use Figure 7B.1 or Figure 7B.2 (as shown in the figure).

2. If the packaging space is insufficient, use Figure 7B.3 and Figure 7B.4 (as shown in the figure) to stick on the front, side or back of the packaging respectively

If you need to know more about the UL 4200A certification process or apply for related certifications, please feel free to consult us!

Label printers entering the Brazilian market, ANATEL certification is an essential passport! It is the recognition of the Brazilian Telecommunications Authority for the safety and compliance of electronic products, without which products cannot be legally sold.

SRRC certification is not only a guarantee of product compliance, but also a key to opening up the market.

FCC ID certification is a mandatory certification for electronic products by the Federal Communications Commission (FCC) in the United States, and it is essential for label printers to obtain this certification.

The UL 4200A-2023 report is mandatory for button batteries because the U.S. Consumer Product Safety Commission (CPSC) has made it a mandatory consumer product safety rule to address the serious threat that button batteries pose to children\'s safety. The implementation of this standard aims to reduce injuries and deaths caused by children aged six and under swallowing button batteries by mistake. UL 4200A-2023 requires that product design should prevent children from easily opening the battery compartment, and stipulates detailed standards for product structure, testing, warning labels and instructions to ensure that products containing button batteries meet strict child protection and safety requirements. Through enforcement, ensure that all relevant products undergo safety verification before entering the market, thereby protecting consumer safety, especially that of children.

Get a quote