In the popularity of smart homes today, sweeping robots have become the "intimate butler" of countless families. As its core power source, the safety performance of the battery directly affects the user experience and equipment life. PSE certification, as a mandatory safety certification for Japanese market access, is not only an "international pass" for product quality, but also a key step for enterprises to expand overseas markets.

First, the significance of certification: the technical scale of safeguarding security

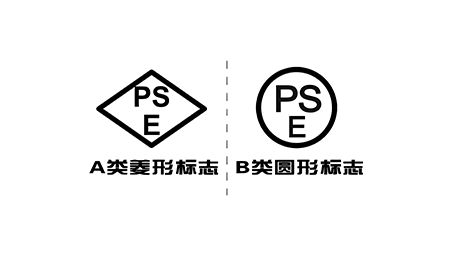

The PSE (Product Safety of Electrical Appliance & Materials) certification is developed by the Ministry of Economy, Trade and Industry of Japan and covers the safety regulations of electrical products. For sweeper batteries, the certification verifies their reliability in high-frequency use scenarios through more than 60 tests such as electrochemical performance, overcharge/overdischarge protection, and thermal stability. According to the Japanese electrical Safety law, lithium battery products that have not obtained the PSE diamond mark are prohibited from sale in Japan, and violators will face product removal and heavy fines.

certification information: scientific and rigorous preparation list

Enterprise application needs to prepare three types of core documents:

1, technical documents: including cell specifications, BMS circuit diagram, thermal management design scheme;

2. Test sample: provide at least 20 sets of unpackaged battery cells and 3 component battery packs;

3, compliance certification: ISO 9001 quality system certificate, raw material UL certification documents, etc.

In particular, it should be noted that the electrolyte MSDS report should clearly mark the flash point, toxicity and other parameters, and the protection board should provide a fault tree analysis (FTA) report.

Third, certification process: four steps to open up market barriers

1. Pre-evaluation stage (3-5 working days) : the laboratory conducts preliminary safety screening of the samples;

2. Formal test period (25-30 working days) : destructive experiments such as extrusion, needling and high-temperature storage are carried out;

3, document review period (10 working days) : the Japanese registration agency to check the technical document compliance;

4, certification record period (5 working days) : certification information into the Japan METI database.

The whole cycle is about 2 months, and it is recommended that enterprises start certification planning 6 months in advance.

Certification value: Triple gain empowers the brand

1, market access: breaking through the Japanese "Electrical products Safety Law" article 2 trade barriers;

2, quality jump: promote enterprises to optimize BMS control strategy, battery cycle life increased by 15% on average;

3. Consumer trust: the premium space of products with the PSE logo reaches 20%, and the re-purchase rate increases by 34%.

4, according to the Japan Household Electrical Appliances Association statistics, 2023 through PSE certification of the vacuum cleaner battery failure rate decreased by 62%, which confirms the certification system for the industry's technical role in promoting. For Chinese enterprises, the advance layout of PSE certification not only means opening the blue ocean market with an annual scale of more than 8 billion yen, but also an opportunity to force the industrial chain to upgrade to high safety standards. In the new era of parallel intelligence and security needs, this thin certificate is becoming the "key to break the game" for the globalization of intelligent enterprises.