Recently, the General Administration of Market Supervision (National Standards Committee) issued the mandatory national standard GB 43854—2024 "Technical Specification for Safety of Lithium-ion Batteries for Electric Bicycles" (hereinafter referred to as "Technical Specification"), which is under the jurisdiction of the Ministry of Industry and Information Technology and will be officially implemented on November 1, 2024.

Scope of application of Technical Specification

The Technical Specification is only applicable to the lithium-ion battery for electric bicycles with the maximum output voltage not exceeding 60V specified in GB 17761 Technical Specification for Safety of Electric Bicycles. It is not suitable for lithium-ion batteries used in electric scooters, balance cars, electric motorcycles, electric tricycles and other vehicles.

The Technical Specification is a mandatory national standard. According to Article 25 of the Standardization Law of People's Republic of China (PRC), "products and services that do not meet the mandatory standards shall not be produced, sold, imported or provided". Therefore, after the implementation of this standard, lithium-ion batteries for electric bicycles sold in China must meet its requirements.

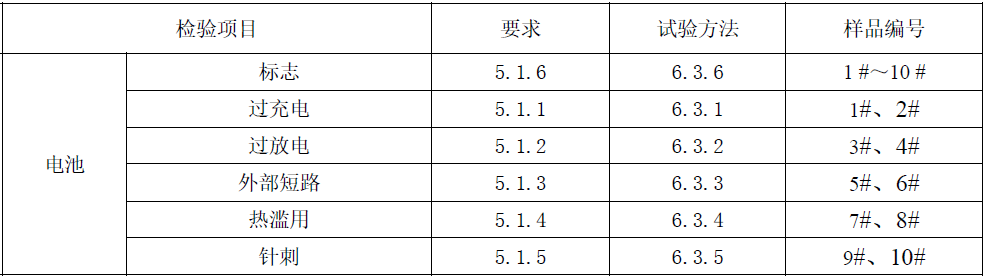

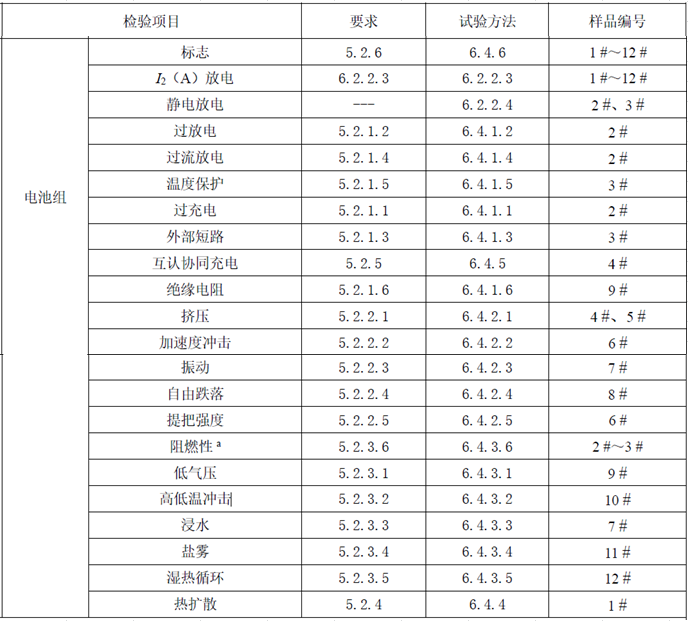

Test items of Technical Specification

The "Technical Specification" stipulates six test items of single battery: including marking, overcharge, overdischarge, external short circuit, thermal abuse and acupuncture; Detailed test item terms and corresponding item sample quantity are shown in the following table:

22 test items of battery pack: including marking, I2(A) discharge, electrostatic discharge, overdischarge, overcharge, temperature protection, external short circuit, mutual recognition and collaborative charging, data acquisition, insulation resistance, extrusion, acceleration impact, vibration, free fall, handle strength, flame retardancy, low air pressure, over-current discharge, temperature cycle, immersion, salt spray, damp-heat cycle, etc. Detailed test item terms and corresponding item sample quantity are shown in the following table:

Key concerns of test project

◆ Overcharge (1.5 times) test and acupuncture test of single battery can effectively screen the safety of battery.

◆ The battery pack shall have a unique code, and the code identification shall be made of high temperature resistant (950℃) material, which can be traced even in case of fire.

◆ Overcharge, external short circuit and over-current discharge tests of the battery pack should be carried out under normal working conditions and single fault condition of protection components, so the battery pack may need to adopt double protection design to meet the requirements.

◆ The battery pack needs to have the function of mutual recognition and collaborative charging, so as to reduce the risk caused by the mismatch of charging devices.

◆ The battery voltage, battery voltage/temperature/current should be collected in real time during the charging and discharging process of the battery pack, which requires the battery pack to be equipped with a management system (intelligent "brain") for real-time monitoring.

◆ The manufacturer should clearly mark the "safe service life" on the battery pack to remind users to eliminate old batteries in time, because with the increase of service life of lithium-ion batteries, their safety risks will gradually increase.

◆ The shell, printed circuit board and wires of the battery pack should be made of flame retardant materials to reduce the spread rate of flame after fire.

◆ The thermal diffusion test of battery pack requires that when a single battery in the battery pack catches fire, it shall not spread to the whole battery pack quickly.

Warm tips

ZRLK has been focusing on the testing and certification of consumer electronic and electrical products for 20 years, always paying attention to the changes of laws and regulations in various countries, and providing customers with one-stop testing and certification services with heart to ensure that enterprise products enter the target market quickly. If you want to know more about the requirements of battery/battery product testing and certification, or if there are batteries/battery products that need to be tested and certified, please feel free to contact us, and our engineers will serve you as soon as possible!

![[Holiday Notice] ZRLK 2026 Chinese New Year Holiday Schedule](/uploads/image/202602/698559be66d97.jpg)