On May 26th, 2023, the International Electrotechnical Commission (IEC) issued the IEC 62368-1:2023 (4th edition) standard. This standard specifies the safety requirements of electrical and electronic equipment (rated voltage not exceeding 600V) using audio, video, information technology and communication technology in the field of business and office machines (excluding the requirements of equipment performance or functional characteristics).

The main technical contents of the new standard and IEC62368-1:2018 (third edition) are changed as follows:

◆ In section 4.1.1, delete "Accepting components and assemblies conforming to IEC 60950-1 or IEC 60065".

It means that the fourth edition no longer accepts components or assemblies certified by IEC 60950-1 and IEC 60065.

◆ Chapter 4.1.8 updated the equipment/components applicable to pressurized LFC test G.15

Delete "G.15 is not applicable to equipment with more than 1L liquid", which means that equipment with more than 1L liquid should also be evaluated.

◆ The test requirements for thermoplastic) T.8 have been added in 4.4.3.1 chapter.

As a safety protection, the untouchable thermoplastic materials also need to do T.8 stress relief test, such as insulating sheets for internal insulation and isolation.

◆ Section 4.8 is added with inapplicable requirements including button cell equipment types and warnings.

The updated section 4.8 is not applicable to the equipment that is unlikely to be taken out by children in button cell, but the relevant battery warning (4.8.2) is required.

◆ Chapter 4.8.3 updated the structural design requirements for button cell protective doors or covers.

Chapter 4.8.3 adds a variety of acceptable structural design types.

◆ Chapter 4.10.3 added the requirements for the main power cord.

It is clear that the power cord only needs to meet the requirements of G.7 power cord, and it is not necessary to use the power cord as an external cord to meet the requirements of Chapter 6, especially the fire protection requirements of the external cord in Chapter 6.5.

◆ 5.5.2.2 chapter has increased the requirements for plug discharge of industrial equipment.

The plug discharge test of industrial equipment with Pluggable equipment type B was added, and the touchable voltage was not measured until 5 seconds later.

◆ 5.6.2.2 chapter updated the color requirements of grounding conductor.

It is clear that the yellow-green color (wire) cannot be used for functional grounding unless it is a multi-purpose preassembled part.

◆ 6.2.3.2 chapter updated the test method of resistive PIS.

The test method of resistive PIS is simplified. When the control fire spread method is used, except for the secondary lithium battery, the parts and conductors in the PS2 circuit are not considered as resistive PIS, and the PS3 circuit is all resistive PIS.

◆ Chapter 6.3.1 updated the parts for which the external material requirements of the fire enclosure are not applicable.

Loudspeaker drivers, mesh cloth, foam, grid covering materials, etc. are added to the parts where the external material requirements of the fire-proof enclosure are not applicable.

At the same time, relevant tests (the requirements are the same as UL60065) for mesh cloth, foam and grid covering materials that need to comply with Appendix S.6 have been added.

◆ Chapter 6.4.6 updated the requirements for controlling the flame spread in the PS3 circuit.

Added that the distance between the varistor and the plastic shell is less than 13mm, and the varistor should meet the requirements of G.8.2, regardless of the fire rating of the shell.

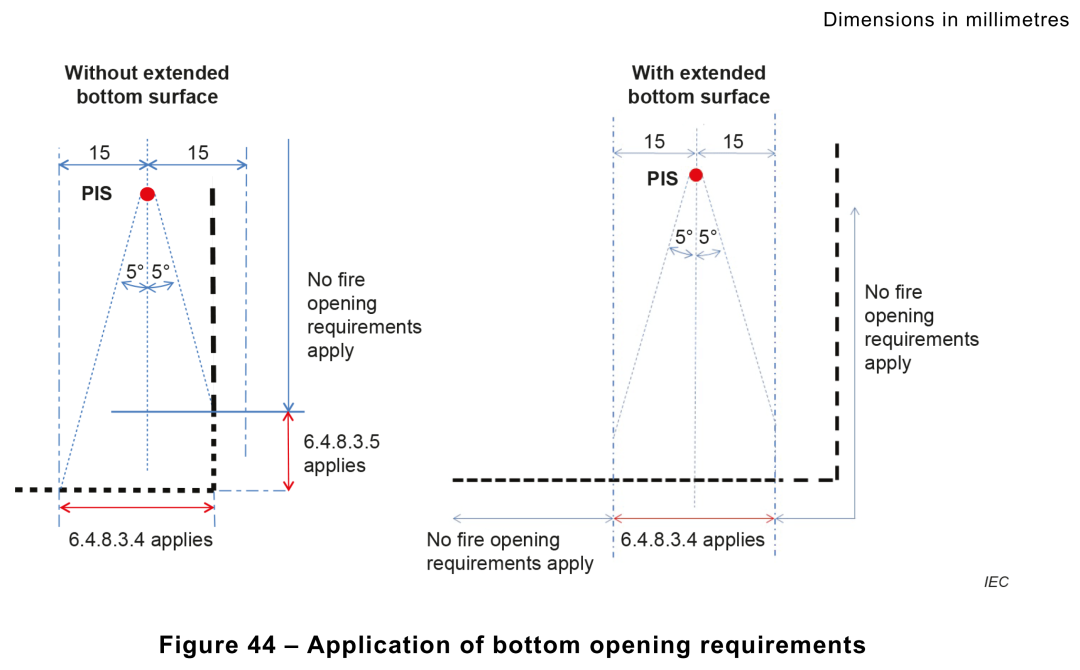

◆ Chapter 6.4.8.3.4 updated the requirements for the opening at the bottom of the fire enclosure.

It is added that flammable materials are unlikely to exist in the surrounding environment of professional equipment (for example, in data centers and server rooms). If the bottom surface of the fire enclosure meets the requirements of 6.4.8.3.4, the Extended bottom surface can be regarded as the applicable opening requirements of the fire enclosure as shown in Figure 44.

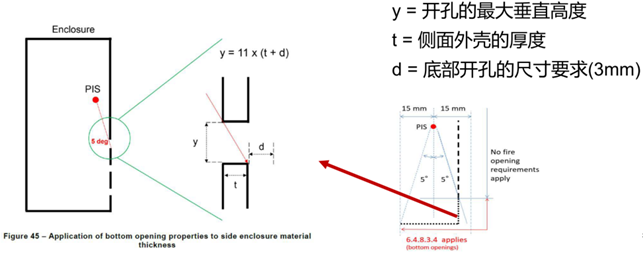

◆ Chapter 6.4.8.3.5 updated the requirements for the opening on the side of the fire enclosure.

The relationship between the lateral thickness and the opening of the fire-proof enclosure is added, which meets the requirements of the lateral opening as shown in Figure 45.

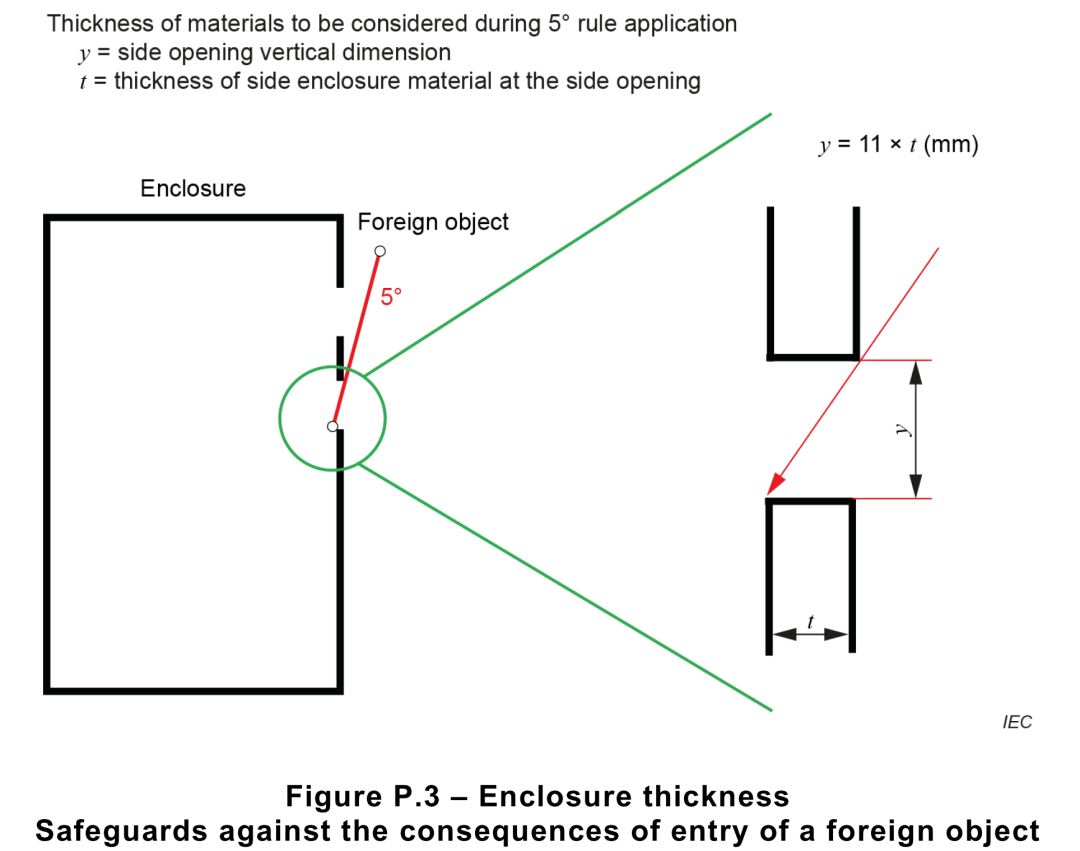

◆ Chapter P.2.1 has updated the requirements for opening holes on the side of the foreign body proof shell.

The dimension of the newly added opening on the side of the shell to prevent foreign objects from entering meets the requirements as shown in Figure P.3, and the maximum vertical height of the opening on the side is less than 11 times the thickness of the side of the shell.

◆ Chapter 9.6 updated the requirements of wireless power transmitter.

It is clear that the test requirements of wireless power transmitter are only applicable to planar transmitter, and if the transmitter is not planar, such as sloping, the test is not applicable.

◆ Chapter 9.6.3 updated the test method and qualification criteria.

Modify the test method: 1). The foreign body should be fixed reliably during the test; 2). The four cycles of testing foreign bodies are done twice respectively. The first time, let the emitter work before releasing foreign bodies, and the second time, let the emitter work before releasing foreign bodies.

The temperature limit value is relaxed.

◆ Section B.2.5 updated the judgment requirements for input test.

The judgment of equipment powered by non-grid power supply has been modified, requiring that the current or power input for testing should not be greater than the rated value of the equipment.

◆ Chapter F.3.5.3 updated the requirements for fuse marking.

It is clear under what circumstances the fuse needs the indicative safety protection and the marking elements of the indicative safety protection.

◆ Chapter F.3.6.2 updated the labeling requirements for Class II equipment with functional grounding.

It is clear which Class II devices with functional grounding need to be marked with functional grounding symbols (IEC 60417-6092).

◆ Chapter G.7.3 updated the requirements of non-detachable soft fixation and stress relief.

It is clear that the interconnecting cable of ES2/ES3/PS3 circuit also needs to be tested for flexible cord stress relief.

◆ Chapter G.15 updated the test requirements for LFC.

The requirements of Self-contained LFC and modular LFC have been added to deal with liquid cooling equipment larger than 1 liter.

◆ Chapter M.4 updated the applicable product categories.

Deleting the word "portable device" means that the requirements of M.4 are also applicable to non-portable battery products, and the range of applicable devices is expanded.

There are additional safety protection requirements when standing equipment with lithium battery is added.

◆ Chapter M.4.3 updated the test requirements for battery cell output PS.

It is clear that the PS energy source needs to be evaluated for single cell or combined cell, and the fire-proof enclosure can be exempted only when the output is below PS1.

Warm tips

ZRLK has been focusing on the testing and certification of consumer electronic and electrical products for 18 years, always paying attention to the changes of laws and regulations in various countries, and providing customers with one-stop testing and certification services to ensure that your products enter the target market quickly. Our company has a professional technical team and rich experience in product testing, and can provide you with a test report that meets the requirements. If you need it, please feel free to contact us, and our engineers will serve you at the first time!