Project Introduction

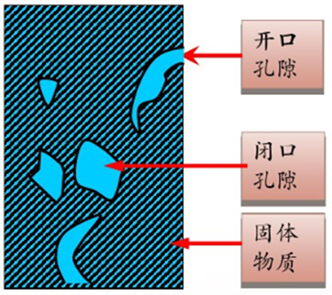

Porosity refers to the proportion of the volume of pores (open and closed) in the volume of the material. Another concept corresponding to the porosity of the material is the density of the material. Density indicates the degree to which the material is filled with solids. It quantitatively reflects the content of solids in the material. The effect on the properties of the material is exactly the opposite of the effect of porosity. The density and porosity of the material reflect the density of the material from different aspects, usually expressed in porosity.

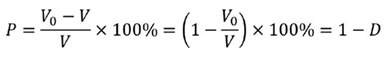

Calculation of porosity

Void ratio = (1-bulk density of the bulk material/apparent density of the bulk material)*100%L void ratio=*100%

Among them: P-porosity of the material,%

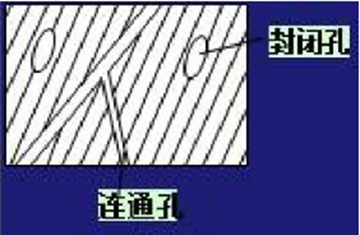

The structure of the void

Connected holes: communicate with each other and communicate with the outside world

Closed holes: independent and isolated from the outside world

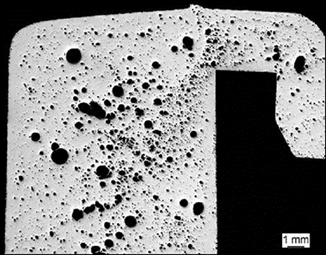

Metal porosity

The porosity of the metal coating refers to the fine pores from the surface of the coating to the base metal. The coating porosity reflects the density of the coating surface, and the porosity directly affects the protective ability of the protective coating (mainly cathodic coating). As a coating with special performance requirements (such as anti-carburization, nitriding, etc.), porosity measurement is also extremely important, it is an important indicator to measure the quality of the coating.

Method Standard

Porosity test method

The national standard GB5935 stipulates the methods for measuring the coating porosity including the filter paper method, the paste method, the dipping method, the anode dielectric measurement of the coating porosity method, and the gas phase test method.

National Standard Reference for Electroplating

The standard of the porosity test of the electroplated coating is: GB/T17721-1999 metal cover porosity test: iron reagent test, GB/T18179--XX metal cover porosity test: wet sulfur (sulfurization) test.

Label printers entering the Brazilian market, ANATEL certification is an essential passport! It is the recognition of the Brazilian Telecommunications Authority for the safety and compliance of electronic products, without which products cannot be legally sold.

SRRC certification is not only a guarantee of product compliance, but also a key to opening up the market.

FCC ID certification is a mandatory certification for electronic products by the Federal Communications Commission (FCC) in the United States, and it is essential for label printers to obtain this certification.

Porosity refers to the proportion of the volume of pores (open and closed) in the volume of the material. Another concept corresponding to the porosity of the material is the density of the material. Density indicates the degree to which the material is filled with solids.

Get a quote